Products

search

|

DCEC QSB6.7-C170 Industrial Engine

|

||||||||||||||||||||||||||||

DCEC QSB6.7-C170 Industrial Engine

Engines has advanced in-cylinder combustion, which improved the reliability and durability, has good inheritence and easier for upgrade.

High pressure common rail fuel system (HPCR) injection pressure is up to 1600bar, achieved multi-point injection, quick resposne of accelerator with different rotate speed, more efficient power output, better fuel economy, lower noise lower fuel consumption.

Mature intelligent electronic control technology, enhance the overall performance of the engine, according to application requirements, the specifications of engine can be customized , higher ability of self-diagnosis and self-protection.

Rear engine power output, high fuel adaptability, suitable for global applications.

Integrated design, fewer spare parts, low failure rate, compact structure, easy to maintain.

High-strength new cylinder design, improvement of displacement, more reliable and durable, low noise, longer use life.

|

Engine Model

|

Rated power/ Speed kW /r/min

|

Max. Torque N.m/rpm

|

Aspiration

|

Emisssion Standard

|

| QSB6.7-200 | 164/2000 | 230/1800 | Turbocharged & Intercooled | Euro III |

| QSB6.7-C130 | 97/2500 | 104/1500 | Turbocharged & Intercooled | Euro III |

| QSB6.7-C170 | 125/2000 | 125/2000 | Turbocharged & Intercooled | Euro III |

| QSB6.7-C190 | 142/2000 | 145/1800 | Turbocharged & Intercooled | Euro III |

| QSB6.7-C220 | 164/2200 | 172/2000 | Turbocharged & Intercooled | Euro III |

| QSB6.7-C260 | 194/2000 | 155/1500 | Turbocharged & Intercooled | Euro III |

|

General Information of DCEC QSB6.7-C170 Industrial Engine

|

|

| Engine Model | QSB6.7-C170 |

| Engine Type | 6 Cylinders, in Line |

| Displacement | 6.7 L |

| Bore | 107mm |

| Stroke | 124mm |

| CPL Number | 43862 |

| Net Weight (with flywleel & alternator) | 520 |

| Overall Diemension(L*W*H) | 1111mm*716mm*960mm |

|

Technical Specification of DCEC QSB6.7-C170 Industrial Engine

|

|

| Certification | Euro III |

| Aspiration | Turbocharged & Intercooled |

| Fuel System | Wuxi weihu Pump |

| Electrical System | 24V, Electric Starting |

| Compression Ratio | 17.2 : 1 |

| Exhaust noise emissions | 112.1 dBa |

|

Performance Data of DCEC QSB6.7-C170 Industrial Engine

|

|

| Rated Power/Speed | 167BHP (125 kW) @ 2000 RPM |

| Max.Torque/Speed | 659N.m @ 1500 rpm |

| Fuel Consumption @ Rated Power | 229 g/kW.h |

| Minimum Low Idle Speed | 600 RPM |

| Maximum Low Idle Speed | 1200RPM |

Performance Curve of DCEC QSB6.7-C170 Industrial Engine

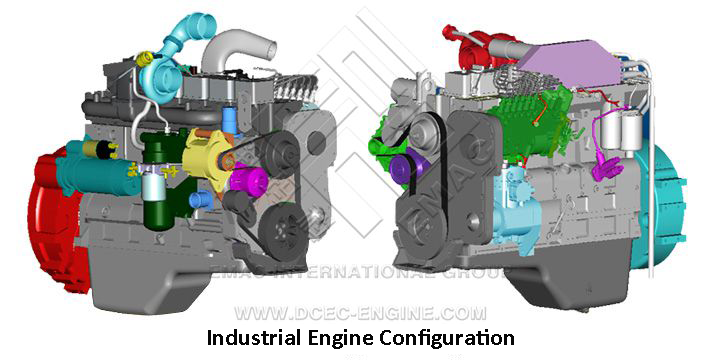

A complete engine with all necessary accessories mainly includes followings:

A complete engine with all necessary accessories mainly includes followings:

| Fuel Injection System | Flywheel | Flywheel Housing | Turbocharger |

| Intake Manifold | Exhaust Manifold | Starter Motor | Alternator |

| Clamp & Hose | Manual & Documents | Oil Filter & Fuel Filter | Water Pump & Oil Pump |

| Fuel-Cutoff-Solenoid |

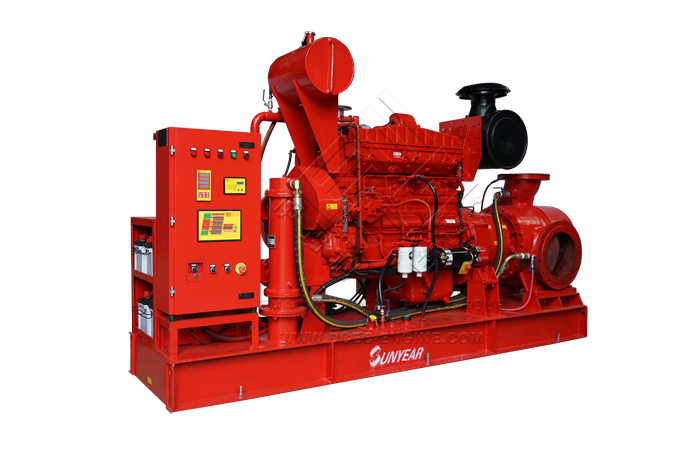

Working together with our business partner Sunyear, we are able to provide a complete power pack for all industrial customers in all over the world. For more information, please visit www.sunyear.com or directly contacting our sales team.

User Guidelines

1. The operating should not out range of the approved number of people and cargo weight.

2. You should take new engine checking and mileage compulsory maintenance when beyond the running travelled distance.

3. You should be clearly that you can’t modify the structure of the engine.

4. if you need to change the spare parts, make sure that you use original spare parts. After-market parts might damage your engine.

5. The quality of lubricating oil using on mechanical B series engine should not lower than API CF-4/SG standard, the viscosity is 15W-40 or when using in the arctic climate 10W-30 and 5W-20. The quality of lubricating oil using on electronic B & C series engine should not than API CH-4/SJ Performance range, the viscosity is 15W-40 or when using in the arctic climate 10W-30 and 5W-20.

6. Your engine must use antifreeze anti-rusted solution, and should change the liquid timely. DCEC recommend to use composite coolant or 50/50 high quality water mix with composite anti freeze.

a. The high quality water should meet all technical requests: concentration of chloride is lower than 40ppm, concentration of sulfate is lower than 100ppm, calcium/magnesium is lower than 170ppm; the prior choice is ionized water, distilled water or softened water.

b. Glycol working range between 40-60% is acceptable.

c. The concentration of SCA is in the range of 0.3-0.8.

|

Data Sheet

|

Diagram

|

Maintenance

|

Operation Manual

|

Order Information

|